Overview

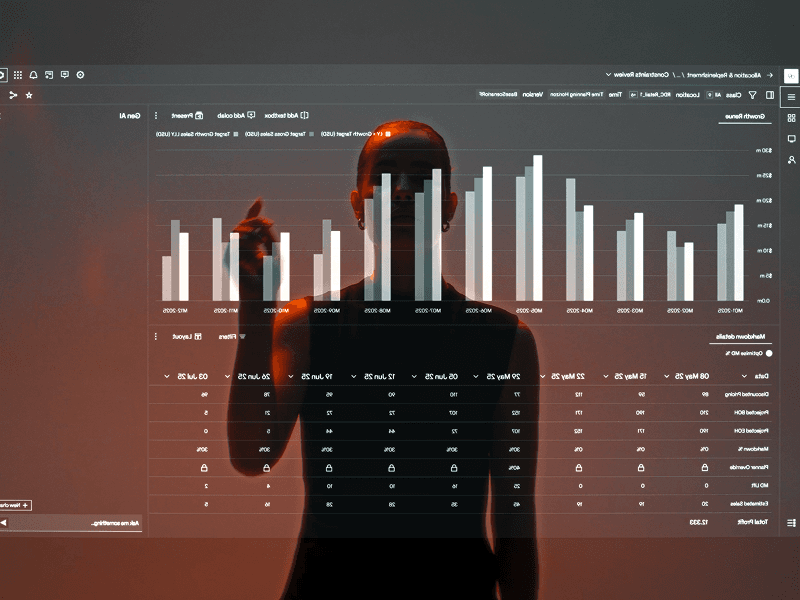

AI-Driven Supplier Risk Management Software for Enterprises

UNLOCKING BILLIONS IN VALUE FOR CLIENTS IN 30+ INDUSTRIES

Move from reactive firefighting to proactive, multi-tier supply chain resilience.

Supplier Risk Management on the o9 Digital Brain enables organizations to identify, quantify, and mitigate supply risks before they disrupt operations or erode margins. By combining multi-tier visibility, financial impact analysis, and collaborative execution, companies can shift from managing isolated risk alerts to building true structural resilience across their supplier networks.

Supplier Collaboration on the o9 Digital Brain enables organizations to replace fragmented, trust-based interactions with structured, data-driven collaboration across procurement, planning, and suppliers. By bringing suppliers directly into the planning process, companies can align cost, capacity, and service decisions in real time — even amid tariff volatility, supply shocks, and regulatory change.

Collaborative Multi-Tier Risk Management

Upgrade your risk management and supply chain resilience with advanced collaborative strategies.

Global supply chains are increasingly exposed to disruption.

Geopolitical instability, natural disasters, financial distress, cyber incidents, and tariff volatility have turned supplier risk into a board-level concern. Yet many organizations still manage risk reactively — responding only after an event has already impacted service, cost, or revenue.

A common challenge is the prevention paradox: investments in resilience are often undervalued until a crisis hits. This is compounded by limited visibility beyond Tier 1 suppliers. Critical dependencies and tariff-sensitive origins frequently sit in Tier 2 or Tier 3, hidden from traditional systems until disruption is unavoidable.

From Alert Fatigue to Structural Resilience

Traditional risk tools generate large volumes of alerts without context. Teams are overwhelmed by noise and forced to triage issues manually, often too late to prevent impact.

Leading organizations are moving toward structural resilience — proactively identifying vulnerabilities, quantifying their financial and operational impact, and embedding mitigation directly into planning and execution. Supplier Risk Management enables this shift by connecting risk signals to the actual parts, suppliers, and orders that matter most.

What this solution enables

Risk Signal Collection and Prioritization

Supplier Risk Management aggregates risk signals from a wide range of external sources, including geopolitical events, weather disruptions, financial indicators, and regulatory changes. These signals are mapped directly to the multi-tier supplier network, allowing organizations to assess relevance and prioritize only those risks that impact critical materials, components, or customer commitments.

Tariff Impact Analysis

Tariffs create both operational and financial risk. o9 automatically links tariff data to the relevant materials, suppliers, and Bills of Material, providing a dynamic view of cost exposure. Side-by-side comparisons of current versus tariff-adjusted landed costs allow teams to understand margin impact instantly and evaluate alternative sourcing or routing strategies.

Multi-Tier Network Modeling

Risk cannot be managed effectively without understanding structure. o9 models the full supply network — including sub-tier suppliers, manufacturing locations, and logistics routes — to uncover hidden dependencies and single points of failure. This visibility allows organizations to identify origin-based risks and upstream bottlenecks long before they cascade downstream.

Stress Testing and Mitigation Scenarios

Supplier Risk Management enables organizations to stress test their supply networks. Teams can simulate scenarios such as supplier failure, capacity loss, or a sudden tariff increase and evaluate mitigation strategies including alternative suppliers, inventory buffering, or production shifts. This ensures preparedness before disruption occurs.

What Makes o9 Different

Risk Integrated with Collaboration and Execution

Identified risks flow into collaborative war rooms, where buyers, planners, and suppliers can jointly assess impact and execute mitigation plans. This closes the gap between awareness and action.Financial Impact Quantification

o9 links risk events — including tariffs and supplier disruptions — directly to financial metrics such as margin, revenue, and unit cost. Leaders can clearly see the economic trade-offs of different mitigation strategies.Actionable, Noise-Free Intelligence

Using the digital twin, o9 determines whether a risk event actually affects a part, order, or customer critical to the business. This dramatically reduces alert fatigue and focuses attention where it matters most.

Industries Supported

Powered by the o9 Digital Brain

Supplier Collaboration is powered by the o9 Digital Brain and its Enterprise Knowledge Graph (EKG).

The platform creates a digital twin of the end-to-end supply network, connecting demand, supply, procurement, finance, tax data, and multi-tier Bills of Material. This single source of truth enables accurate impact analysis — such as identifying which sub-components are affected by tariffs based on origin and processing location.

Rapid scenario planning allows teams to simulate tariff changes, supplier de-commitments, or sourcing shifts and compare financial and operational outcomes side by side.

The o9 Digital Brain

The digital brain is powered by our patented Enterprise Knowledge Graph (EKG)

Modular by design, enterprise by default

Supplier Risk Management is built on a multi-tier digital twin that continuously senses risk, quantifies impact, and drives mitigation across the supplier network — before disruptions reach operations or customers.

Core Building Blocks

These foundational components establish multi-tier visibility, risk context, and execution alignment.

Enterprise Knowledge Graph (EKG) & Supply Chain Digital Twin

The EKG models the physical supply network across suppliers, sub-tiers, materials, routes, and locations. It creates a live digital twin that allows risks to be assessed in structural and operational context.

Unified Risk Data Ingestion Layer

Aggregates external risk signals such as geopolitical events, weather disruptions, financial stress, and tariff changes. Signals are normalized and mapped directly to relevant suppliers, materials, and BOMs.

Multi-Tier Network Mapper

Provides unconstrained modeling of Tier 2 and Tier 3 dependencies to expose hidden risks and single points of failure. Enables early identification of origin-based and sub-tier vulnerabilities.

Risk-Aware Control Tower & Exception Framework

Surfaces only risks that materially impact critical parts, orders, or customers. Exceptions are prioritized based on probability, impact, and time-to-effect.

Advanced Building Blocks

These components apply AI and simulation to move from alerting to proactive resilience.

AI Risk Management Agents

Transforms abstract risk events (e.g., tariff hikes, supplier insolvency) into concrete supply impacts such as lead-time shifts, cost exposure, or capacity loss. Effects are propagated to revenue, margin, and service.

Scenario Planning & Stress Testing Engine

Enables rapid simulation of supplier failure, tariff escalation, or logistics disruption scenarios. Mitigation strategies are evaluated side by side across cost, service, and risk reduction.

Master Data Validation & Cleansing Intelligence

Continuously validates lead times, lot sizes, and supplier parameters against transactional behavior. Ensures risk decisions are based on accurate, trusted data.

Predictive Risk Analytics

Uses machine learning to identify recurring patterns such as chronic supplier delays or degradation trends. These signals act as early warnings for structural risk.

Take a Tour

See how the o9 Digital Brain unifies planning, forecasting, and execution through AI-driven intelligence.

A digital operating model for VUCA conditions

APEX is o9’s AI-powered operating model for enterprises navigating volatility, uncertainty, complexity, and ambiguity (VUCA). It enables organizations to plan, execute, and learn as one connected system.

The o9 Digital Brain powers APEX by connecting enterprise data, knowledge, and decisions through a single intelligent model.

Collaborative Demand Planning is one of the building blocks of the Digital Brain. It contributes domain-specific capabilities into the enterprise-wide model that enables APEX from the ground up—linking this solution to decisions across the entire value chain.

→ Learn how the APEX Operating Model works

Where AI drives real decisions

Artificial intelligence enables risk management at scale.

Risk management agents autonomously identify emerging risks, assess probability and impact, and generate multiple mitigation scenarios, such as rerouting, alternative sourcing, or inventory repositioning.

Master data cleansing agents ensure risk models are built on accurate parameters by continuously validating lead times, lot sizes, and supplier attributes against transactional data.

Predictive analytics detect recurring patterns — such as chronic supplier delays — that signal structural vulnerabilities before they escalate into crises.

→ Learn more about o9 AI innovations

Advanced Risk Management: Steering Supply Chains Safely Through the Storm

Global supply chains are susceptible to a wide range of disruptions, from natural disasters and geopolitical tensions to technological failures and economic fluctuations.

Results in real-world complexity

Telco Network Equipment Manufacturer

This organization struggled with a high volume of risk alerts and reactive responses that consumed planner capacity.

By integrating external risk data with o9’s supply chain planning processes, the company automated scenario generation and mitigation evaluation for alternative suppliers and materials. The result was a 96% reduction in alerts requiring manual attention, allowing risk managers to focus on true threats with sufficient lead time.

What our customers say

Take a Tour

See how the o9 Digital Brain unifies planning, forecasting, and execution through AI-driven intelligence.

Related solutions

Digital IBP

At its core, IBP is designed to translate strategic intent into coordinated, financially sound actions across the enterprise. Yet in many organizations, IBP has devolved into a monthly cadence of spreadsheet reconciliation, slide preparation, and functional compromise—producing alignment in theory, but limited impact in practice.

Sales & Operations Planning (S&OP)

Connect strategic planning with day-to-day execution — without breaking alignment or financial control.

Supplier Collaboration

Move from transactional sourcing to continuous, multi-tier orchestration across your supplier network.

Frequently Asked Questions (FAQ)

Supplier risk management identifies, assesses, and mitigates risks arising from suppliers and sub-tier dependencies that could disrupt supply, increase cost, or impact service.