Turning Supply Chains into a Competitive Advantage: Insights from aim10x Asia

8 read min

As diverse as Asia is—spanning cultures, languages, and economies from China and Korea to Thailand, India, and beyond—a common thread emerged at aim10x Asia. Held at the stunning Flower Field Hall in Singapore’s Marina Bay, the event brought together nearly 150 senior business and supply chain leaders who revealed that leading companies across the region are confronting many of the same structural challenges. Fragmented systems, disconnected data, and increasing market volatility are limiting visibility and slowing decision-making. Yet these very challenges are also becoming powerful catalysts for change, driving a new wave of digital transformation built on integration, intelligence, and agility.

How Will Pandora Achieve Planning Excellence?

Pandora, the world’s largest jewelry brand, designs and crafts more than 100 million pieces of jewelry each year, serving customers through over 6,500 points of sale in 100 countries. With vertically integrated operations—from crafting facilities in Thailand to retail boutiques worldwide—Pandora’s supply chain is both vast and complex.

Despite its scale, Pandora’s planning processes were fragmented across more than five different ERP platforms. This siloed setup made it difficult to see the end-to-end impact of decisions. As Pieter Pennings, VP of Supply Chain & Sustainability, explained, “we tried to keep inventory low, but couldn’t show what the benefit would be on the revenue side.” The lack of connected visibility limited collaboration and slowed decision-making across the organization.

To address these challenges, Pandora launched HERO—an integrated planning program powered by the o9 Digital Brain platform. Short for Harmonize, Elevate, Respond, and Optimize, HERO embodies Pandora’s ambition to harmonize its systems, elevate its people and processes, and create a more agile, data-driven organization. The o9 platform serves as the technological foundation for HERO, connecting planning across stores, distribution centers, and factories to enable true end-to-end visibility and scenario-based decision-making.

With o9 as the digital backbone of HERO, Pandora is well on its way to making smarter, enterprise-level decisions—ones that “might not look favorable to one department, but are right for the company overall,” as Pieter noted.

Why Transforming Planning and Decision-Making Is Key for Indorama’s Growth

Indorama Ventures, a $15B global leader in chemicals, fibers, and packaging, has grown rapidly through acquisitions, leaving a patchwork of systems and processes across 114 sites in 32 countries.

Decades of M&A created 24+ ERPs and siloed processes, making it “Herculean” to pull even basic performance data. As Gaurang Oza, VP & Global IBP Process Lead for Fibers, noted, volatility has also accelerated: “thirty years ago, disruptions came every four to six years; today, they happen every quarter.” An initial push on working-capital reduction in a $3.5B division surfaced a deeper need: a common, digital backbone to plan and decide at enterprise speed.

Indorama turned to the o9 Digital Brain to establish a unified Integrated Business Planning (IBP) platform. The rollout began with targeted pilots tailored to each line of business:

- Demand planning for CPET and Fibers

- Supply planning for Chemicals

- KPI measurement across two businesses

This phased approach created a scalable, standardized foundation while respecting unique business dynamics.

According to Gaurang, the results have been encouraging. “User engagement has been very strong. We’re currently in our first demand cycle, and a couple of businesses are doing live demand reviews today on the platform.”

How Mankind Pharma Is Enabling Supply Chain Resilience at Scale

With 25 factories, 2,000 active SKUs, and operations spanning India’s vast, often unpredictable geography, Mankind Pharma faces one of the most complex supply chain environments in the region. Seasonal disruptions, shifting demand patterns, and diverse regional markets make ensuring on-time medicine availability a constant challenge. As Kunal Bansal, Chief Digital Officer, put it, “A medicine is only as good as its availability.” The company needed a connected, intelligent system that could anticipate disruptions, respond with agility, and ensure that every patient received what they needed, when they needed it.

To achieve this, Mankind launched a two-year digital transformation roadmap centered on Resilience, Responsiveness, and Orchestration. Led by Deepanjan Ghosh, Associate Vice President of Supply Chain Digital Transformation, the initiative replaced static, calendar-based planning with event-driven, AI-supported decision-making powered by the o9 Digital Brain. “Users shouldn’t be debating data; they should be debating decisions,” Deepanjan emphasized. Through o9, the team implemented end-to-end digital planning—covering demand, supply, and distribution—as well as S&OP and transport load optimization.

The results have been transformative. “We’ve seen a significant dip in loss of sales—about eighty percent,” Deepanjan shared. “And we’ve achieved around a twenty percent reduction in inventory through better planning and target optimization.” The benefits, however, go beyond numbers.

Kunal highlighted how the platform has changed the organization’s mindset: “We’re not arguing about whether the data is correct anymore. We’re discussing why there’s an inventory shortfall and how to optimize.”

How Amway Reimagined Forecasting for a New Era

Amway is the world’s “number one direct-selling company… generating about seven point four billion dollars.” A lean team of 24 planners manages about 21,000 SKUs and “more than seven hundred market-level forecasts.” The scale outpaced legacy ways of working. The organization needed one planning environment that could connect top-down and bottom-up views, align shop and market planning, and anchor collaboration in reliable data and KPIs.

Led by Bo-Kyung Ko, Manager of APAC Demand Planning, Amway defined four design principles: organizational responsiveness, process agility, collaboration through data and KPIs, and sustained investment in tools and people. After two years of design and evaluation, the team selected the o9 Digital Brain. Rollout followed a disciplined path: pilot first, then scale, supported by extensive training and actionable dashboards that brought shop-to-global visibility into a single solution.

The payoff has been tangible and heard directly from users. As Bo shared, teams “just went fully live last week,” are seeing “real-time visibility from shop to global,” and feel “more empowered and much more efficient.” Measured results back this up: a +9-point accuracy lift in the Korea pilot and +4 to 5 points across the first rollout wave within six months.

The mindset has shifted as well. “Go-live isn’t the finish line,” Bo emphasized. The roadmap now moves from today’s statistical models toward AI and machine learning, sustained by “strong partnerships” across Amway, o9, and market teams.

How Tapestry Is Reimagining Planning for a Multi-Brand Future

Tapestry, the parent company of Coach and Kate Spade, operates across 84 countries with millions of units moving through its global supply chain. Yet much of that complexity was still being managed through Excel and Access. As Aidan Le-Devenish, Vice President of Global Supply Chain Planning, explained, “We recognized that was a risk… we couldn’t truly cost-optimize the supply chain that way.” The company needed to move beyond spreadsheets, eliminate siloed decision-making, and reduce its dependence on the “tribal knowledge sitting only in people’s heads.”

After evaluating five vendors, o9 emerged as the unanimous choice for its end-to-end planning capabilities. “We knew our long-term goal was to have an end-to-end planning solution—from materials to logistics,” Aidan said. The transformation, powered by the o9 Digital Brain, is focused on creating a single digital environment where buying, sourcing, and product development teams can collaborate seamlessly. Strong change management and disciplined execution have been essential. Aidan highlighted o9’s adaptability as a key differentiator: “Midway through blueprinting, o9 actually adapted the model to add a tariff lens to cost optimization, which was huge for us.”

As Tapestry moves toward go-live, early results show stronger cross-functional alignment and smarter decision-making. The company is preparing for destination-based allocation that will “level-load the supply chain and deliver real cost optimization.” Looking ahead, Aidan envisions a fully connected, intelligent ecosystem—one where demand, materials, logistics, and container planning all come together to support Tapestry’s multi-brand, multi-market future.

How Can Digital Transformation Elevate Supply Chains into a Competitive Advantage?

Godrej Consumer Products Limited (GCPL), a $1.7 billion FMCG leader, operates across a highly dynamic and competitive market. Traditional supply chains, as Vishal Gupta, Head of Business Transformation & Digital for India & SAARC, explained, often struggle with “fragmented systems, manual processes, and data silos.” These challenges result in poor visibility, inaccurate forecasts, and inefficiencies that ripple across production, logistics, and customer service. Vishal believed the answer lay in building a supply chain that was “connected, intelligent, and adaptive, creating an end-to-end ecosystem with one version of truth that can sense changes and react automatically.”

Over the past two years, GCPL has reimagined its supply chain from demand to delivery, powered by a modern digital backbone that integrates SAP S/4HANA with automation across procurement, forecasting, logistics, and manufacturing. At the center of this transformation sits the o9 Digital Brain, which Vishal described as “the bridge between demand planning and execution.” o9 converts demand signals into daily production and dispatch plans across 20 manufacturing sites, 150 lines, 500 SKUs, and 30 warehouses, enabling planners to make real-time, data-driven decisions that optimize both cost and service.

The benefits have been both operational and cultural. With o9, planners can now optimize production at the “line-day-SKU level” and dispatch at the “lane-day-SKU level,” achieving higher fill rates, lower inventory, and improved responsiveness to market shifts. Vishal emphasized that success is not just about technology: “You can have the best system in the world, but if the data isn’t right, your output will be wrong.” By embedding data discipline, process standardization, and agility into its operations, GCPL is transforming its supply chain from a cost center into a true strategic advantage—one designed not just to survive disruption, but to thrive through it.

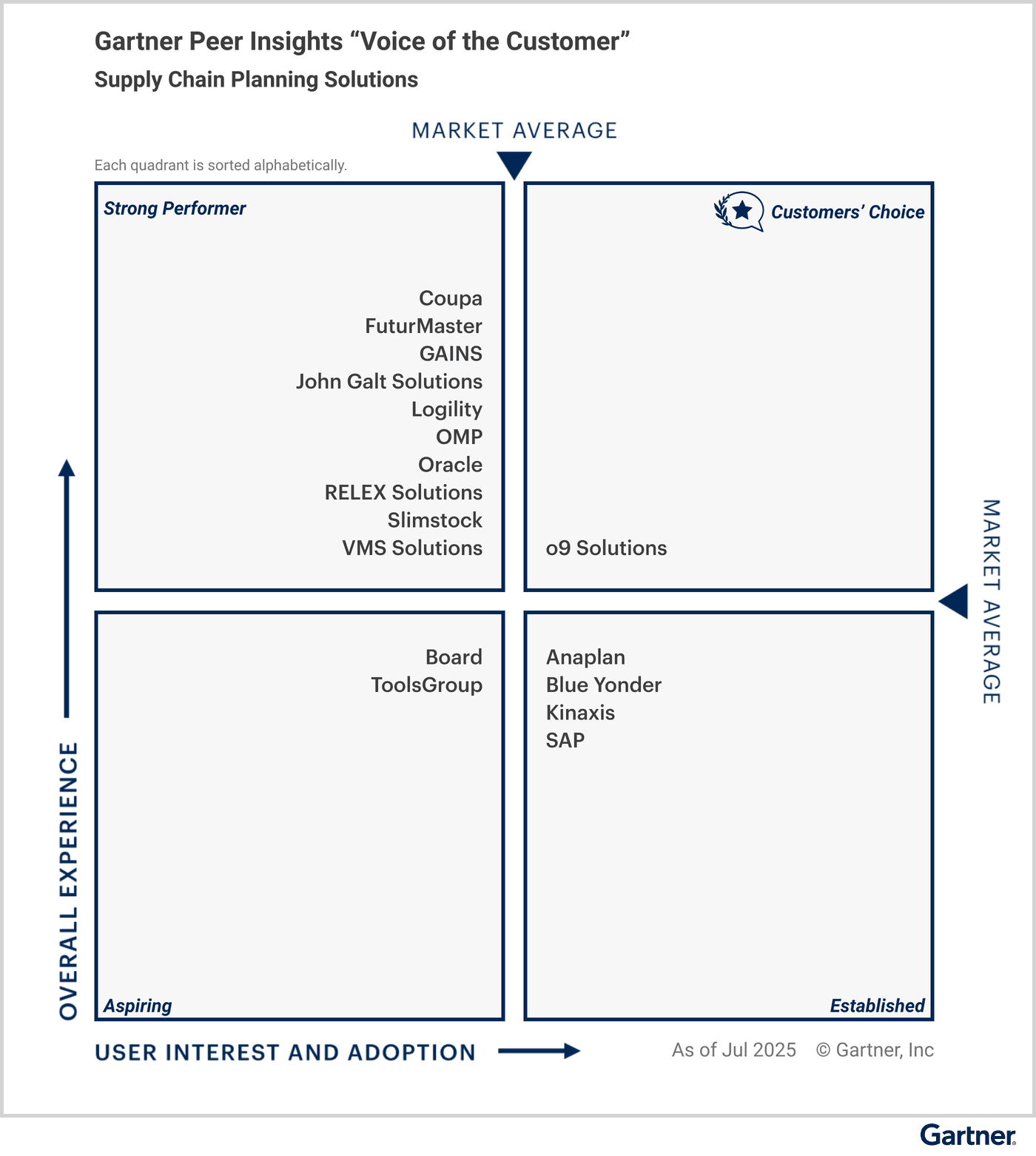

o9 Recognized as the only “Customers’ Choice” Provider

o9 is the only vendor to be recognized as a Customers’ Choice in the 2025 Gartner® Peer Insights™ Customers’ Choice for Supply Chain Planning Solutions. o9 was the only software provider that met or exceeded the market average scores for both Overall Experience and User Interest.

About the authors

o9

The Digital Brain Platform

o9 Solutions is a leading Enterprise Knowledge and AI-powered platform helping companies build Agile, Adaptive & Autonomous Planning & Execution Models for transforming enterprise decision-making in environments of rising volatility and uncertainty. Whether it is improving forecast accuracy, matching demand and supply and driving collaboration across the multi-tier supply chain to improve resilience at optimal costs and inventory, or optimizing new product and commercial initiatives to drive revenue growth and margins, decision-making processes from long-range to tactical to execution horizon can be made faster and smarter and connected on o9’s Digital Brain Platform.

o9 brings together game-changing technology innovations — such as innovative enterprise knowledge graph modeling, big data analytics, advanced algorithms for forecasting, demand/supply balancing, scenario planning, real time learning, collaboration, generative and agentic AI, easy-to-use interfaces and cloud-based delivery, and innovative management methods — as well as organization, process and change management best practices to transform decision-making speed and intelligence.

on this page